I will show you a process I’ve developed for fusing glass onto common red clay brick. Yes, you shouldn’t be able to do that because of the difference in the Coefficients of Expansion (COE), a.k.a. Coefficients of Thermal Expansion (CTE) between brick and glass. Nevertheless, it is possible to get glass to stick very well to brick.

In 1999 I began an experiment to test the feasibility of fusing glass onto brick for a 97-foot long three brick high garden wall. This was

the result: 97' long fused glass-on-brick project... http://www.peltier-info.com/wall.html

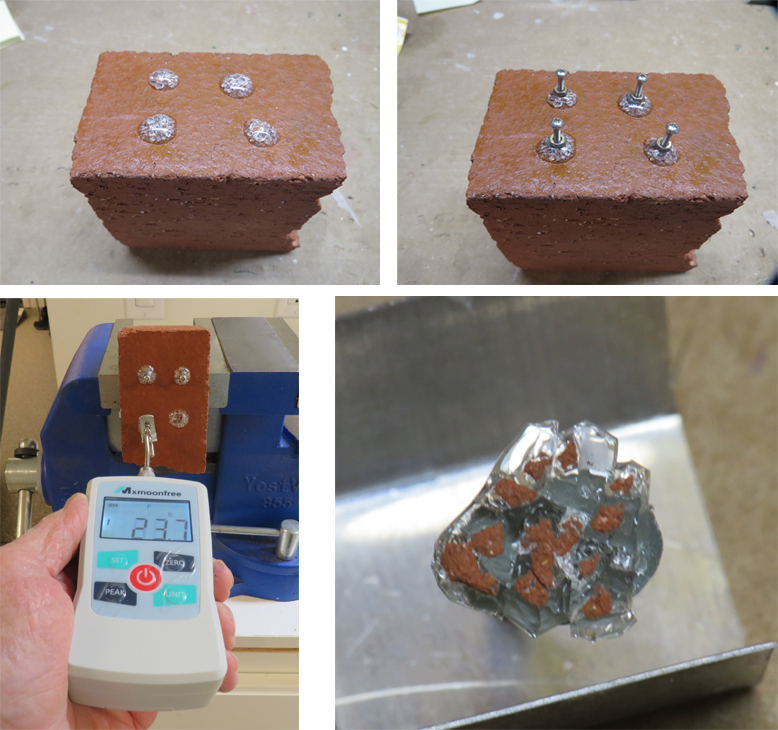

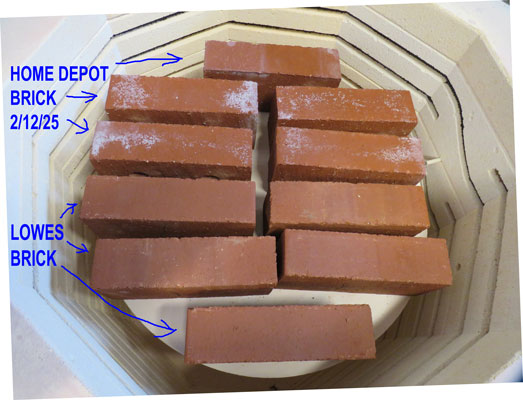

Perfecting The Process...I undertook more serious experiments to improve the glass adhesion than I did 25 years ago. The original process was to soak the brick face in Sodium Silicate, also known as “Water Glass” for a number of hours. After that dried, stained glass was laid on top and fired in a kiln at glass fusing temperatures. Key to perfecting the process was to actually measure adhesion of the glass to the brick. This was done by fusing small disks of glass to brick, glue a steel screw to the fused glass and measure the breakaway strength when the screw was pulled. For the screw I used 2-56 stainless screws and nuts. The nuts were glued to the fused glass and the screw head was captured by a slotted hook. The hook pulled by a Mxmoonfree ZMF 500 Newton digital force gauge (Amazon, ~$66.) When the glass breaks apart or pulls brick from the brick the gauge records that maximum reading in pounds. To be sure to test the glass adhesion to the brick and not the adhesion of the screw to the glass I tested seven epoxies. All epoxies were cured for 24 hours and the screws were glued to ordinary window glass. The winner was Loctite EA 9340 with a greater than 42 lbs average breakaway strength, followed by PC-SuperEpoxy at 39.5 lbs and Stick Fast 5 Minute at greater than 35 lbs.

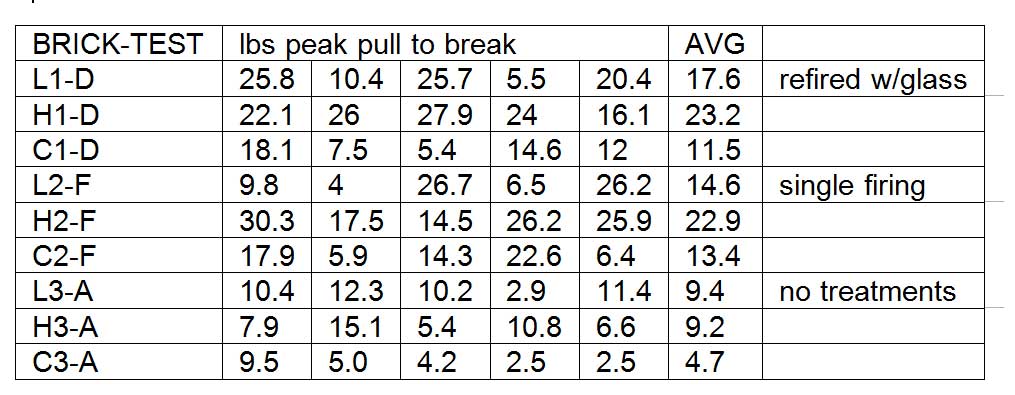

The Brick... I use common red clay brick from Home Depot. At the time of this writing it is 67 cents per brick. I tested both red clay bricks from Home Depot and Lowes and settled on the Home Depot stock as it was cheaper. Also, in two out of three glass adhesion tests the Home Depot brick fared better than the Lowes. I do not know why as they appear identical.

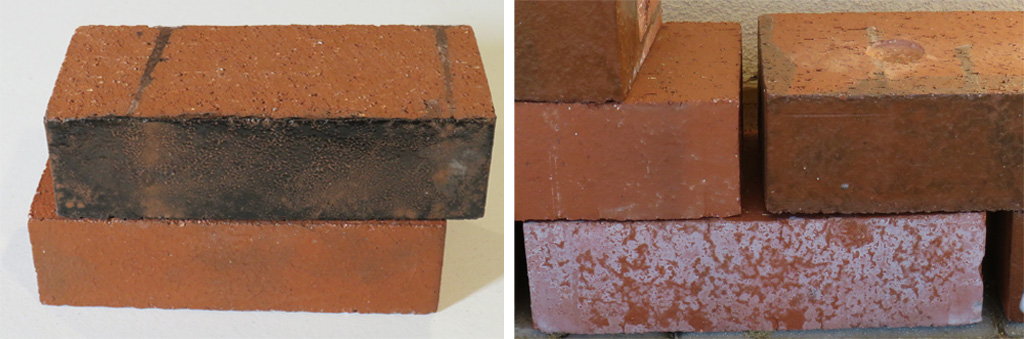

IMPORTANT UPDATE!... After about 80 bricks, all from Home Depot, disaster! Upon baking a batch of bricks to make sure that they were dry a white deposit was driven to the surface. I thought it was efflorescence, not uncommon in brick, but vinegar did not dissolve it as expected. Some sort of contamination in the brick that never appeared before. It did not appear upon baking or firing the next batch of brick from Lowes. Lesson learned... always be sure to dry bricks first, 100F to 220F.

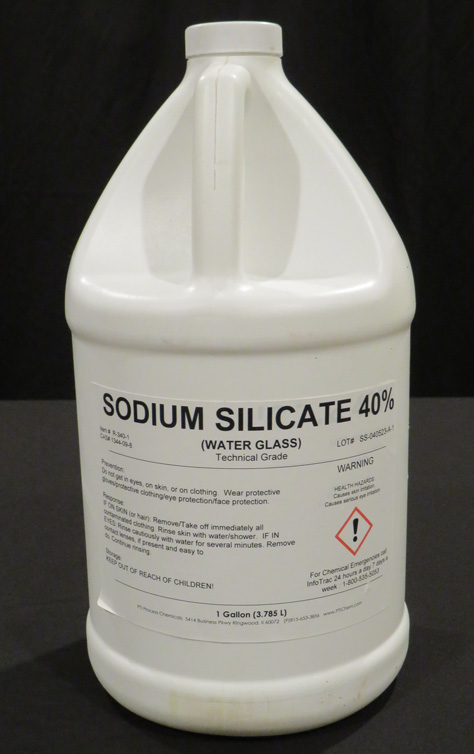

Sodium Silicate... The first step is coating the brick face with Sodium Silicate, also known as “Water Glass.” This is painted on the brick face first. The brick should be dry, and after the Sodium Silicate coating it should be kept dry. I store the brick in my kiln set to 100F to keep it dry before and after coating. It takes about 3/4 of a teaspoon (3.7 ml) to coat the brick. I use a chip brush for the application. For my latest experiments I am applying the Sodium Silicate only directly under the glass in hopes to eliminate the occasional white deposits that have appeared on brick where there is no glass. I get the Sodium Silicate 40% in one gallon jugs for under $20 from McMaster-Carr, p/n 3190K251.

Drying Brick... I notice that 10% of the bricks came out very dark after firing. This was strange as all of the bricks seemed quite identical with identical Sodium Silicate coatings. I suspected that although appearing identical some bricks had a higher moisture content and that might have been the cause. I started keeping new bricks in the kiln set to 100F before and after the Sodium Silicate applications and that has solved the problem. Further investigations measured brick water content using a probe meter with a setting specifically for brick: Uncoated unfired red clay brick stored in 44% RH garage: 0.2% Finished fired brick stored in 44% RH garage: 0.2% Coated and fired stored outside in 60% RH damp weather: 3% Sodium Silicate coated unfired brick stored in 100F kiln: 0% It appears one should use brick of under 0.2% to assure no darkening.

The Glass... I tested two common stained glasses, COE 90 and COE 96. For this application COE 90 fared better with less cracking, so I use that exclusively. That usually means Bullseye opaque glass which is widely available.

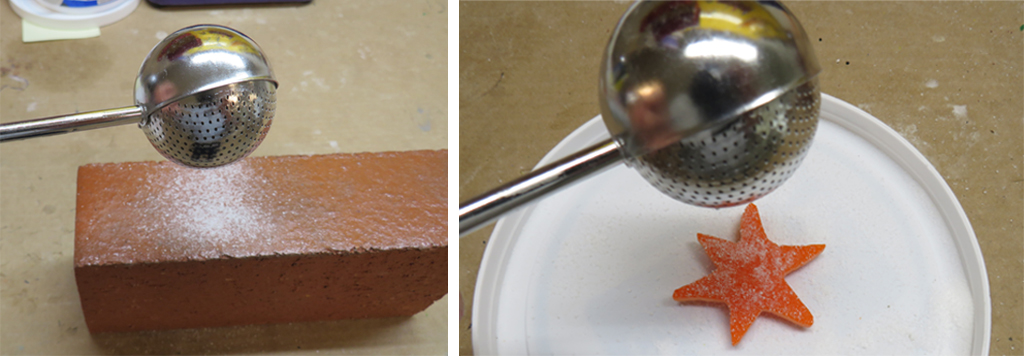

Borax... Borax is the key to the improved glass-on-brick success! Borax seems to act as a flux to cause the glass to melt, flow, and wet the Sodium Silicate coated brick better. Borax treated brick yielded almost twice adhesion of Sodium Silicate-only treated brick, measurements as high as over 50 lbs pull! I used plain Borax, Birch & Meadow unscented from Amazon, under $8.

Borax application... Two methods were used, one was to shake powdered Borax on the brick, lay the stained glass on it, then blow or brush away what was not under the glass. Borax left exposed on the Sodium Silicate brick resulted in a very shiny surface which for my uses was not desirable. I use an OXO Good Grips Baker’s Dusting Wand. The other method was to apply a thin coating of Bullseye GLASTAC GEL to the underside of the stained glass piece, dust that with Borax, then lay Borax-side down on the brick. The optimum amount of powdered Borax? I have no idea.

Kiln Firing... I fire the bricks at 1450F, a fairly rapid heating rate of 690F/hour, and a 5 minute hold at 1450F. Gradual cooldown with kiln closed. The result is that the glass melts and flows well, but not too well. In my kiln a longer hold or higher temperature can results in loss of shape of the glass pieces as it flows a bit too much.

The Glass Cracks... Yes, the glass does crack. There is no way around that due to the differences in COE. The COE of the glass used is 90. The COE of red clay brick is hard to pin down, but I’ve seen figures in the 55 to 70 range. The key point is the glass nonetheless does hold together well and it adheres quite well to the brick. The cracking is barely visible if you use opaque glass.

Weathering... I have tested glass on brick using the new techniques with multiple wet/freeze/thaw cycles with no apparent negative effects. I was concerned that water could get in the unavoidable micro cracks in the glass and damage it when the water ice expands, but have not witnessed this happening. Regarding fading... Stained glass does not fade in sunlight. The color is not painted on but is an internal chemical part of the glass.

The Future... I need to do another five or so 10-foot scenes before cementing all of them in place. You are encouraged to further work to perfect this process! I strongly suggest that you be scientific about it and do actual adhesion tests as I did, otherwise you’re working in the dark.

Other links that may be of interest...

The Glass Block Pond:

Glass Block Walkway Lights:

Glass Block Walkway Lights... http://www.kissingfrogs.tv/blocklights.html

Round Patio with Custom Tiles:

Round Patio with Custom Tiles... http://www.kissingfrogs.tv/roundpatio.html

A White Light Emitting Diode (LED) lit Patio Cover:

White Light Emitting Diode (LED) lit Patio Cover... http://www.kissingfrogs.tv/patiocover.html

A gilded metal wind sculpture of fish:

Flying Fish Swim with the Breeze... http://www.kissingfrogs.tv/windsculpture.html

Lecture / Demonstration Light Tower:

Lecture / Demonstration Light Tower... http://www.kissingfrogs.tv/lighttower.html

Water Lily Pots with Integral Feeding Tubes:

Easy to Feed Water Lily Pots... http://www.kissingfrogs.tv/lilypots.html

Details of a unique bamboo and gilded copper garden trellis:

Bamboo and Gilded Copper Trellis... http://www.kissingfrogs.tv/trellis.html

An Illuminated Glass, Gold, and Copper Birdbath:

Glass, Gold, and Copper Birdbath... http://www.kissingfrogs.tv/birdbath.html

A unique 97-foot long fused glass-on-brick project:

97' long fused glass-on-brick project... http://www.peltier-info.com/wall.html

Directory of over 100 pond supply dealers:

Pond Dealer Directory... http://www.kissingfrogs.tv/ponddirectory.html

A permanent Heron-deterrent Scarecrow installation:

Heron-deterrent Scarecrow Installation... http://www.kissingfrogs.tv/scarecrow.html

Homemade Mini Glassworking Lathe:

Homemade Mini Glassworking Lathe... http://www.kissingfrogs.tv/glasslathe.html

Home Made Bird Feeder LED Yard / Walkway Lights:

Home Made Bird Feeder LED Yard / Walkway Lights... http://www.kissingfrogs.tv/yardlights.html

Gopher Screen - keep moles and gophers from ruining your lawn:

Gopher Screen - keep moles and gophers from ruining your lawn... http://www.kissingfrogs.tv/gopherscreen.html

Largest Thermoelectricity information site on the 'net:

Thermoelectricity information site... http://www.peltier-info.com

Largest used high-tech equipment dealer directory on the 'net:

Largest used hi-tech equipment dealer directory... http://www.big-list.com

LED Light Emitting Diode spectral scans and measurements:

LED Spectral Scans... http://www.big-list.com/leds.html